Surface Curvature Correction

The Surface Curvature Correction tool removes curvature from curved surfaces while preserving surface features or defects, using a configurable polynomial order (the tool performs a 2D polynomial fit on X and Y to process surfaces). You can then use the tool's output as input to other measurement tools to apply measurements to the "flattened" surface.

The tool does not support rotational scans (that is, polar "unwrapping").

In the following images, a curved surface (top) is flattened out (bottom), preserving the surface detail.

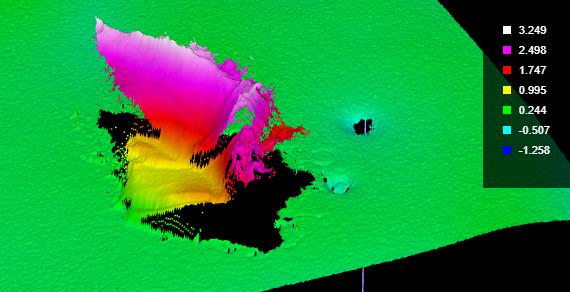

The original, curved scan of a target.

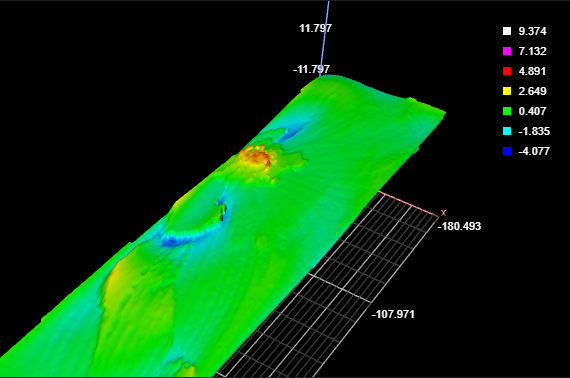

The "flattened" surface data (the tool's Difference Surface data output).

In the following image, a Surface Dimension tool's height measurement runs on the "flattened" output (the Surface Curvature tool's Difference Surface output) to determine the height of one of the raised areas:

Height of a raised feature relative to the flattened surface.

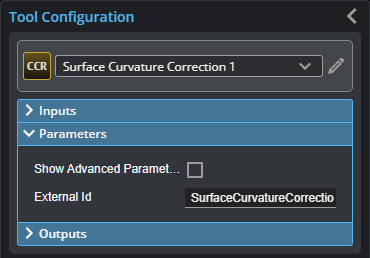

For information on adding, managing, and removing tools, as well as detailed descriptions of settings common to most tools, see Tool Configuration.

Inputs

You configure the tool's inputs in the expandable Inputs section.

| Name | Description |

|---|---|

| Enable Batching |

For more information on arrays, batching, and aggregating, see Arrays, Batching, and Aggregation. |

|

Surface Input |

The data the tool applies measurements to or processes. |

Parameters

You configure the tool's parameters in the expandable Parameters section.

| Parameter | Description |

|---|---|

|

Show Advanced Parameters |

Enables a set of advanced parameters. (See Advanced Parameters.) |

|

External ID |

The external ID of the tool that appears in GoHMI Designer. For more information, see GoHMI and GoHMI Designer. |

| Parameter | Description |

|---|---|

|

Number of Regions |

Lets you specify and configure one or more regions the tool will process. Use this parameter to limit the tool to specific areas on the target. |

|

Exclude Features |

Lets you exclude features or surface details from the polynomial fit. This can allow you to get a better fit on the surrounding surface. Checking this option enables the Negative area, Positive area, and Iterative Steps parameters. (See below.) For example, in the following scan data, we would like to accurately measure the circular divots and the small hole near the center of the data on the curved surface.

If the large feature to the left is not excluded for the polynomial fit, the measurements on the smaller features will be inaccurate. In the following "flattened" scan data, without excluding the larger feature, the smaller features would be difficult to accurately measure:

When the larger feature is excluded from the polynomial fitting, the surrounding surface and the smaller features are more properly "flattened."

|

|

Polynomial Order |

Selects the order (or degree) of the polynomial to be fit to the surface. A higher order results in a better fit but increases processing time. |

|

Sampling Step |

The step in data points in both directions with which the surface is sampled. Choosing a higher sampling step reduces the processing time the tool requires, but reduces fit accuracy. Useful if the surface being processed has a large number of data points. |

|

Iterative Steps |

The number of times the tool repeats the feature exclusion calculation (see Exclude Features, above). |

|

Negative area Positive area |

These settings exclude the specified percentage of a histogram of the height values of the scan data from the bottom up (Negative area) and from the top down (Positive area), respectively. |

|

External ID |

The external ID of the tool that appears in GoHMI Designer. For more information, see GoHMI and GoHMI Designer. |

Outputs

All tools provide measurements, geometric features, or data as outputs.