EtherNet/IP Protocol

You can use an EtherNet/IP programmable logic controller (PLC) over Ethernet to operate a sensor and receive measurement values. EtherNet/IP only supports a subset of the tasks that can be accomplished in the web interface (for example, starting and stopping sensors, and switching jobs). Scan data can't be sent to the PLC.

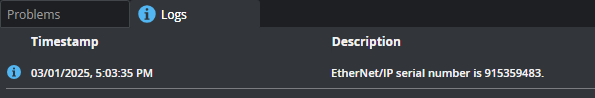

When you enable the protocol, a log entry displays the EtherNet/IP serial number you should use in your PLC.

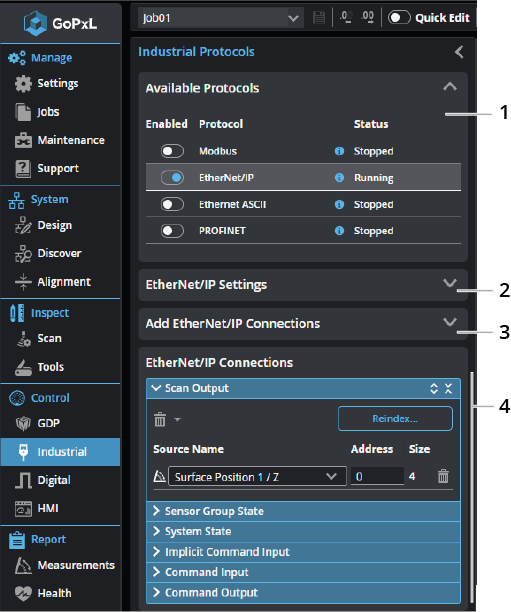

You configure the protocol on the Control > Industrial page. After configuring the EtherNet/IP protocol in GoPxL (see below), use the information in EtherNet/IP Protocol Format - PLC Information to configure your PLC.

| Element | Description | |

|---|---|---|

|

1 |

Available Protocols |

Click a row in the table to choose which protocol to configure. Enable a protocol by toggling the slider to the right. |

|

2 |

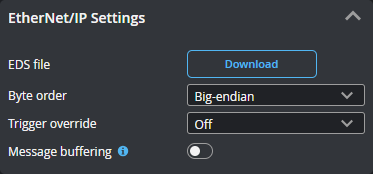

EtherNet/IP Settings |

You configure the protocol's settings in this section.

EDS file Click Download to save an EDS file to the client computer for later installation on the PLC.

Byte order One of the following: Big-endian: The most significant byte (the "big end") of the data is placed at the byte with the lowest address. The rest of the data is placed in order of decreasing significance in the next three bytes of memory. Little-endian: The least significant byte (the "little end") of the data is placed at the byte with the lowest address. The rest of the data is placed in order of increasing significance in the next three bytes in memory. Most Allen-Bradley PLCs default to Little Endian addressing formats, but you should verify this when configuring the PLC.

Trigger override One of the following: Off, Cyclic, and Change of State. When you set up the PLC to communicate with a Gocator using change of state implicit messaging, an event task must be created on the PLC to rapidly check whether the sensor is running; if the frame count increases, data is copied to an array. The event task period must allow the event task to be executed at a higher rate than Gocator frame rate.

Message buffering Used to enable and disable buffering of scan outputs. You should enable buffering if you are using part detection and if multiple objects may be detected within a period shorter than the polling rate of the PLC. If buffering is enabled with the EtherNet/IP protocol, the buffer is automatically advanced when the Sample State assembly object is read (see EtherNet/IP Protocol Format - PLC Information). Message buffering only applies to tool outputs sent over explicit messaging. For more information on part detection, see Continuous in Surface Generation. |

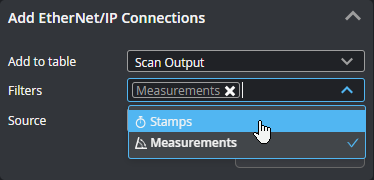

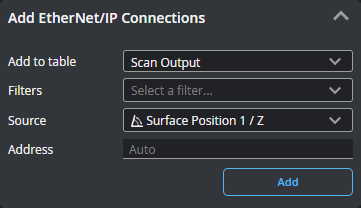

| 3 | Add EtherNet/IP Connections |

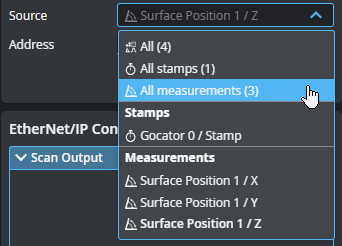

Lets you add sources (such as stamps or measurements) to send over the protocol. Added connections appear in the EtherNet/IP Connections section at the bottom of the panel. When GoPxL is running on a standalone sensor (one not controlling others), Add to Table only contains one value (Scan Output) that represents a register assembly. When GoPxL is running on a sensor controlling other sensors, or on a PC or GoMax NX, Add to Table contains an additional entry (Sensor Group State). Use this to choose which register a source is added to. If you have many sources, you can filter them by type to make it easier to find the source you want in the Source drop-down . You can enable more than one filter.

Choose the source in the Source drop-down. If you leave Address as "Auto", GoPxL automatically increments the value; otherwise, you can set it yourself. By default, connections are added directly after the last source in the connections map. You can optionally set the address at which a source is added using the Address parameter.

You can also add all sources, or all sources of a given type.

Click Add to add the source to the EtherNet/IP Connections table below. |

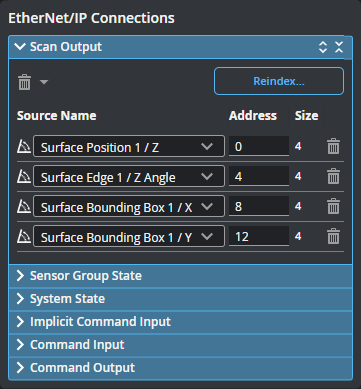

| 4 | EtherNet/IP Connections |

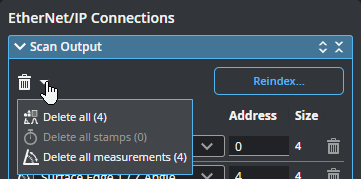

The connections listed here will be sent by the protocol to a compatible PLC. You can delete a connection using the trashcan icon in its row, or change its ID. When changing an ID, make sure to use the size of the source to correctly calculate the minimum offset.

You can also use shortcut commands to delete all of the connections, or specific categories of connections.

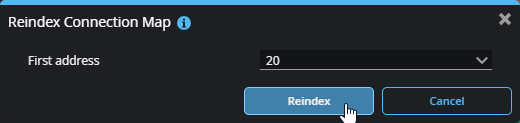

Use Reindex... to remove gaps of unused addresses between connections. You can also set the value of the first index.

|