Surface Mesh

|

This tool is only intended for use with G2 sensors. |

|

You must enable the Enable Processing parameter for this tool to produce output. |

|

Always set this tool's input to the Surface data being produced by the sensors. |

The Surface Mesh tool takes in an XML transformation file produced by the Surface Align Ring tool (see Ring Layouts (Surface Align Ring Tool)), and stitches scan data from multiple sensors into a single mesh, which is typically a 360-degree scan. (That is, when sensors are in a ring configuration.) You can apply some measurements directly to the resulting Mesh scan data, or you can use the Mesh Projection tool to extract a surface from any angle of the Mesh data, and apply any of the other Surface measurement tools to the extracted surface.

Note that the tool's settings (most of which are visible only if you select a sensor from the Sensor Parameters drop-down) are populated by loading the XML transformation file produced by Surface Align Ring.

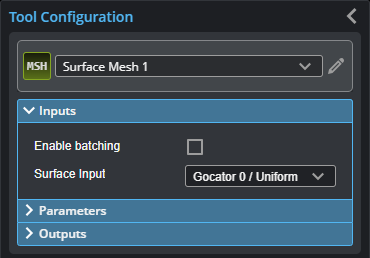

Inputs

You configure the tool's inputs in the expandable Inputs section.

| Name | Description |

|---|---|

| Enable Batching |

For more information on arrays, batching, and aggregating, see Arrays, Batching, and Aggregation. |

|

Surface Input |

The data the tool applies measurements to or processes. |

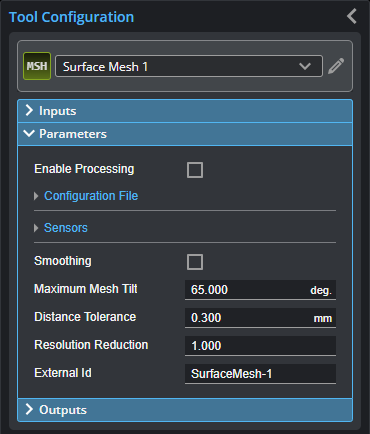

Parameters

You configure the tool's parameters in the expandable Parameters section.

| Parameter | Description |

|---|---|

|

Enable Processing |

Causes the tool to start processing scan data from individual sensors, combining it into a Mesh data output. Make sure to load the XML |

| Configuration File | Expandable section containing configuration file operations and alignment status. |

|

Operation |

Actions that apply to the tool's XML configuration files. The files are located in C:\GoTools\SurfaceAlign. One of the following:

|

|

Alignment Status |

Indicates whether the tool has aligned the sensors. Either "Not Aligned" or the date and time of the alignment. |

| Sensors | Expands to show sensor-related settings. |

|

Sensor Count |

Sets the number of sensors in the system. |

|

Sensor Parameters |

A drop-down that lets you display the settings of a specific sensor. You do not usually need to change these settings, as they are set when you load the XML file produced by Surface Align Ring using the Operation drop-down. The values are intended for diagnostics only. For information on the parameters, see Sensor Parameters. |

| Smoothing | If enabled, applies smoothing to each sensor’s frame before stitching them together. Set the smoothing level in Smooth Window. For low density surfaces, you should disable smoothing to preserve the edge details. |

| Smooth Window |

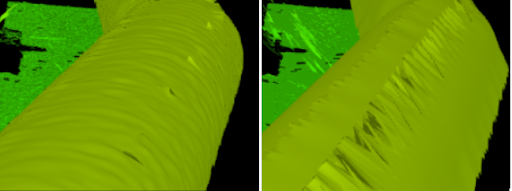

Sets the smoothing level. In the following, smoothing level is disabled on the left, and set to 5 on the right.

|

|

Maximum Mesh Tilt |

The maximum acceptable angle between a sensor's XY plane and the generated mesh triangles. Using a smaller value can result in a cleaner transition where the Surface scan data of individual sensors are stitched, reducing the inclusion of outlier data points or the creation of artifacts. |

|

Distance tolerance |

The maximum acceptable distance between the data points in overlapping Surface data. |

| Resolution Reduction | Reduces the lateral resolution of the heightmap to reduce processing time. |

|

External ID |

The external ID of the tool that appears in GoHMI Designer. For more information, see GoHMI and GoHMI Designer. |

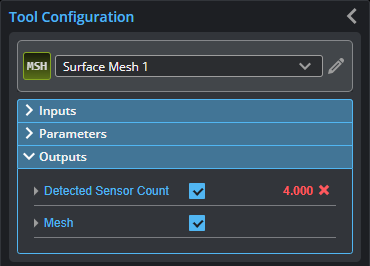

Outputs

All tools provide measurements, geometric features, or data as outputs.

| Measurement |

|---|

|

Detected Sensor Count The number of sensors detected in the system. |

| Type | Description |

|---|---|

|

Mesh |

The Mesh data resulting from combining the scan data of the individual sensors. This data output can be taken as input by the Mesh tools (see Mesh Measurement). Use Mesh Projection or Mesh Plane to extract Surface data from this output, which can then be measured using any Surface measurement tool. |